Aftermarket Worryfree 14mm 3 Layer Bobbin Coil Former Bobbin for Transformers Coils Pot Core

Aftermarket Worryfree 14mm 3 Layer Bobbin Coil Former Bobbin for Transformers Coils Pot Core

Transformer/Inductor Bobbin Sizes. I have to design a 150 Ampere, 1.5 mH Inductor for a power supply project assigned to me, and off-the-shelf components are to be used. My instructor is insistent on using a transformer Bobbin to wind the conductor around, however wants me to optimize the design to standard bobbins available commercially.

Windings calculator for a amplifier viprock

Linear Transformers Communications/RF Switch Mode Power Current Transformer Unlikely Yes Possible Possible Unlikely Yes Possible Possible Unlikely Yes Unlikely Possible Unlikely. Bobbin Type and Size "A" "B" RM Bobbins EFD Bobbins PQ Bobbins EP Bobbins. B-EIM41X25V-12-1-PBT BC-EIM41X25V-12-1-PBT B-EIM41X30H-10-2-GFN3 B-EIM42X14.8H-10.

Transformer Plastic Bobbin at Rs 5/piece Transformer Bobbins in Pune ID 19811914948

Most Janome home machines use a Class 15 bobbin. Most Nolting machines use an L-style bobbin, however, M-style variants are available. Most Pfaff machines except for the newer Creative Vision and Quilt Expressions 4.0 use an L-style bobbin. This information has been passed on to us by our customers, we can not confirm it is 100% accurate.

EE20 Transformer Bobbin Horizontal (6+6P) FM2065

A transformer bobbin, also known as a coil former, is a vital component in the manufacturing of transformers. It serves as a container to hold wires, channels and supports the winding, facilitates easy insertion of the magnetic core, and provides connection and termination methods. Benaka Electronics has established capability to produce high.

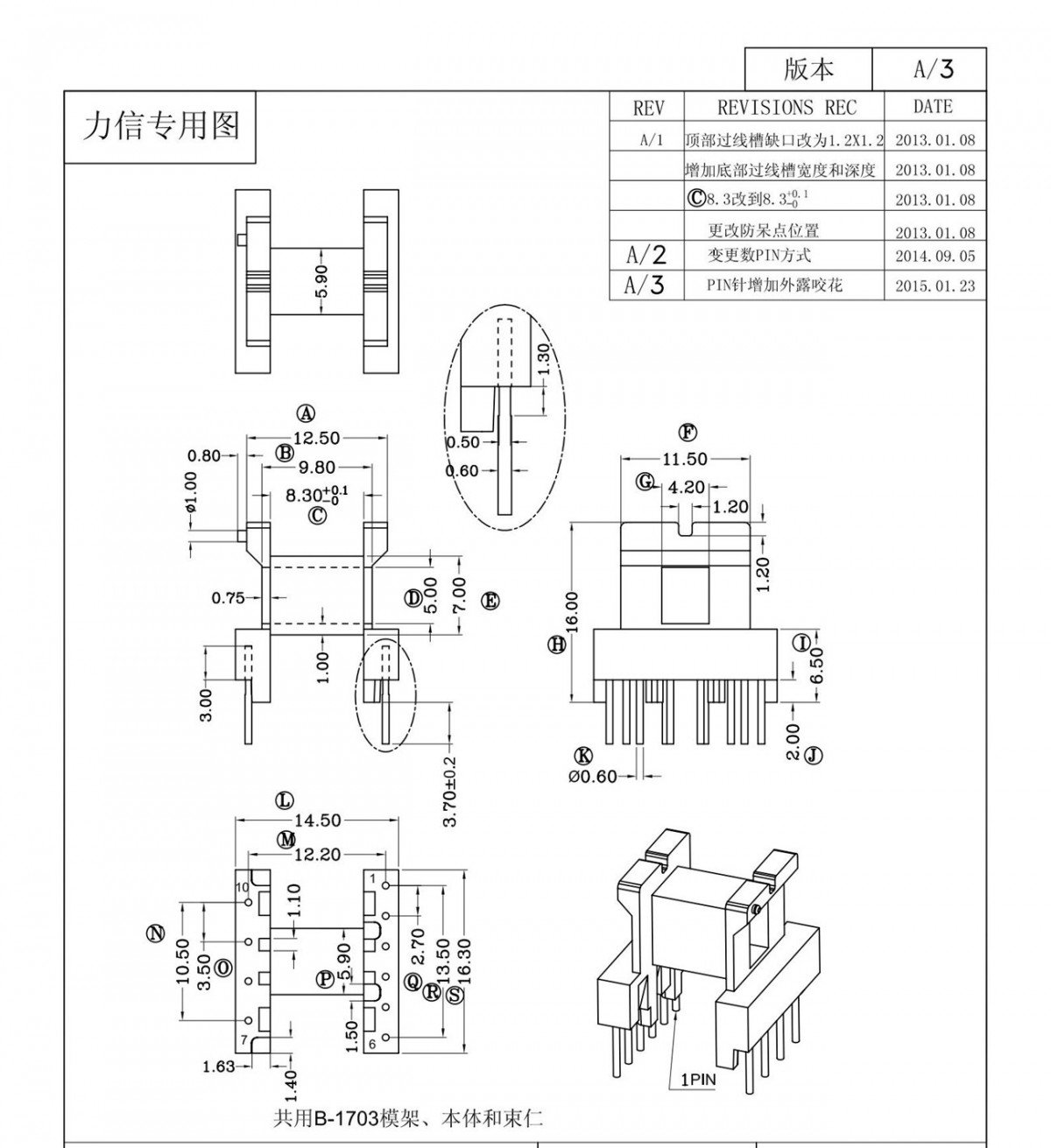

EE16 Horizontal Transformer Bobbin (4+6Pin) F1667

bobbins to cover the "in between" lamination range (EI150 to EI300) that help address the needs of the larger transformer industry. The finished article- 15kVA bobbin wound assembled transformer using a 3" x 6" bobbin with UL94V0 flammability, Class N 200°C Lamination Centre Limb Size USA/ UK reference Stack Heights

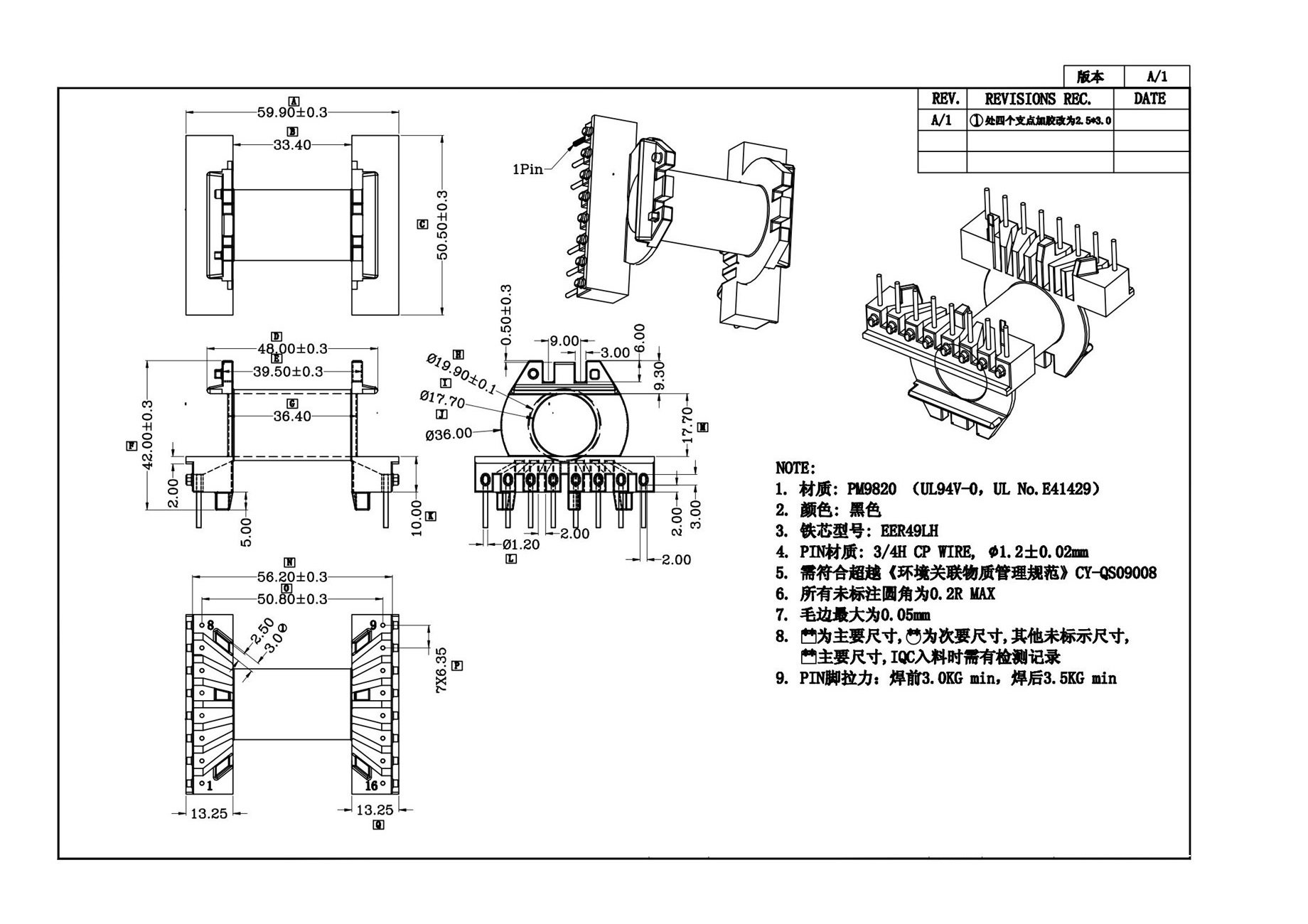

EER49 Horizontal Transformer Bobbin(8+8Pin) F4909

Bobbin manufacturer's catalogs are used to provide mechanical dimensions for transformer design. The bobbin manufacturers in Appendix A offer a wide variety of bobbin styles for standard ferrite core sizes in materials suitable for high volume production. Many ferrite core manufacturers also carry bobbins for their standard core sizes. PI-1907.

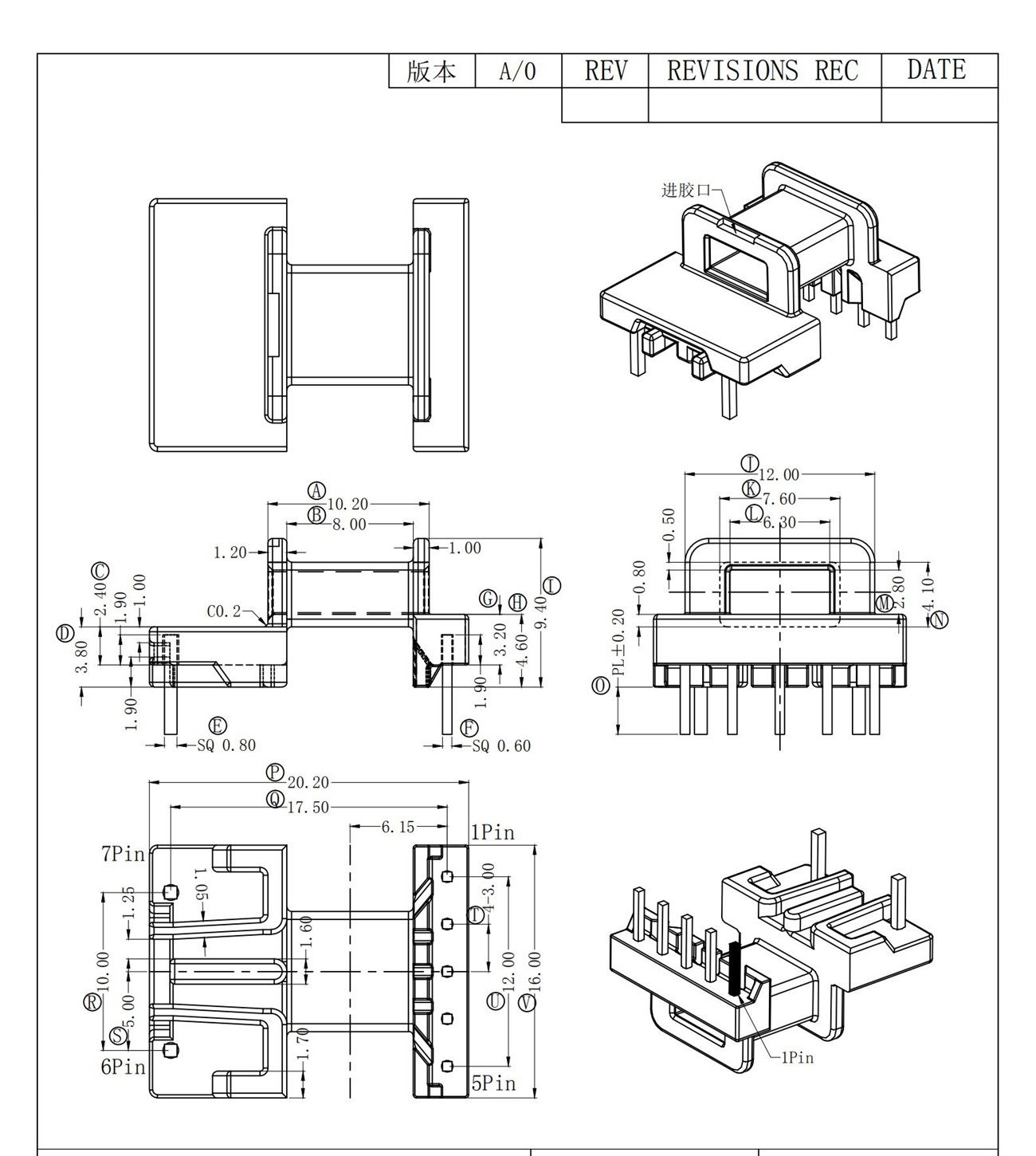

EFD25 Transformer Bobbin Horizontal (5+7Pin) F25102

round bobbin, shown in Figure 4-8, will provide the most compact design. It can be seen, in Figure 4-8, that the round bobbin provides a uniform tension, all 360 degrees around the bobbin, for both layer and random windings. The other benefit, in using a round bobbin, is the reduction and minimizing of the leakage inductance caused from the bowing.

EE16 Horizontal Transformer Bobbin(5+2P) F16123

With core parameters calculated and confirmed we now need to calculate the appropriate wire sizes. First requirement is to calculate the available bobbin width (BW A) from the actual bobbin width (BW), the number of layers for the primary winding (L) and the margin width (M). The primary winding can be 1, 2 or 3 layers, but

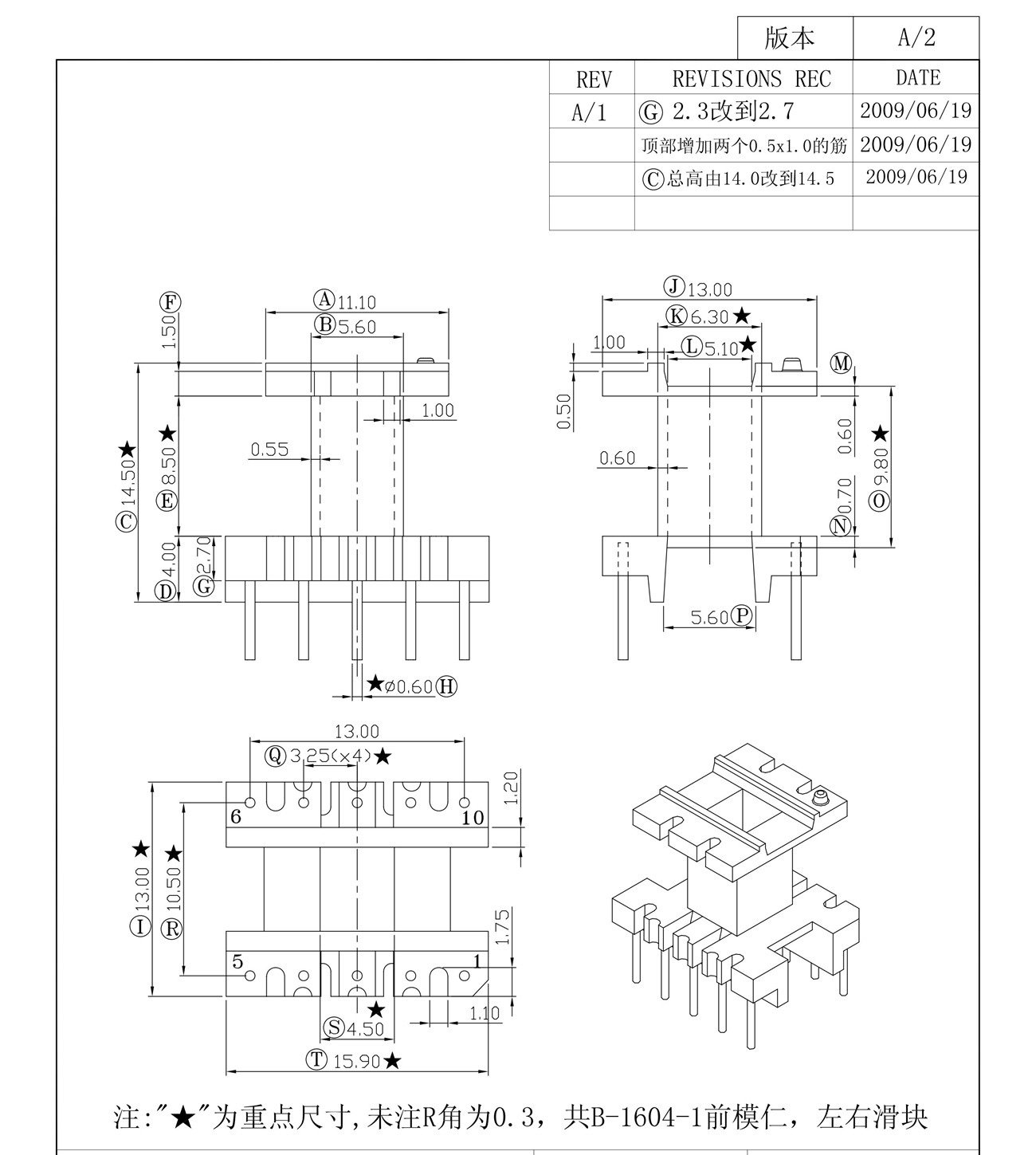

EE16 Transformer Bobbin Vertical (5+5P) F1604

These lamination stampings when connected together form the required core shape. For example, two "E" stampings plus two end closing "I" stampings to give an E-I core forming one element of a standard shell-type transformer core. These individual laminations are tightly butted together during it's construction to reduce the reluctance of the air gap at the joints producing a highly.

Transformer Bobbins • ASCO Components Transformer parts

P. S. Leakage inductance is a measure of how much magnetic flux couples from the primary into the secondary. The greater the distance between the primary and the secondary, the fewer flux lines there will be to couple the two windings together. Fewer flux lines coupling the windings means larger values of leakage inductance.

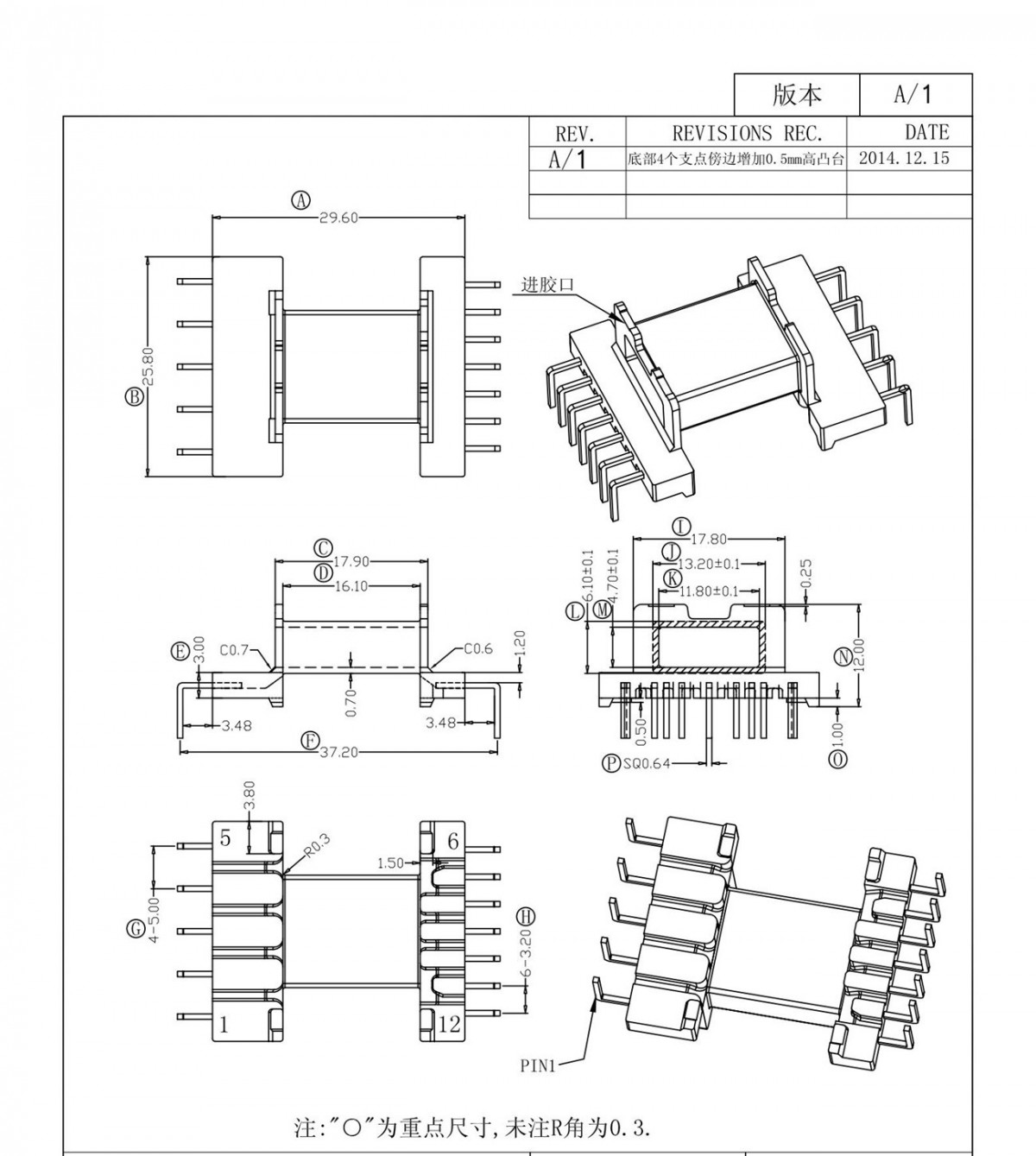

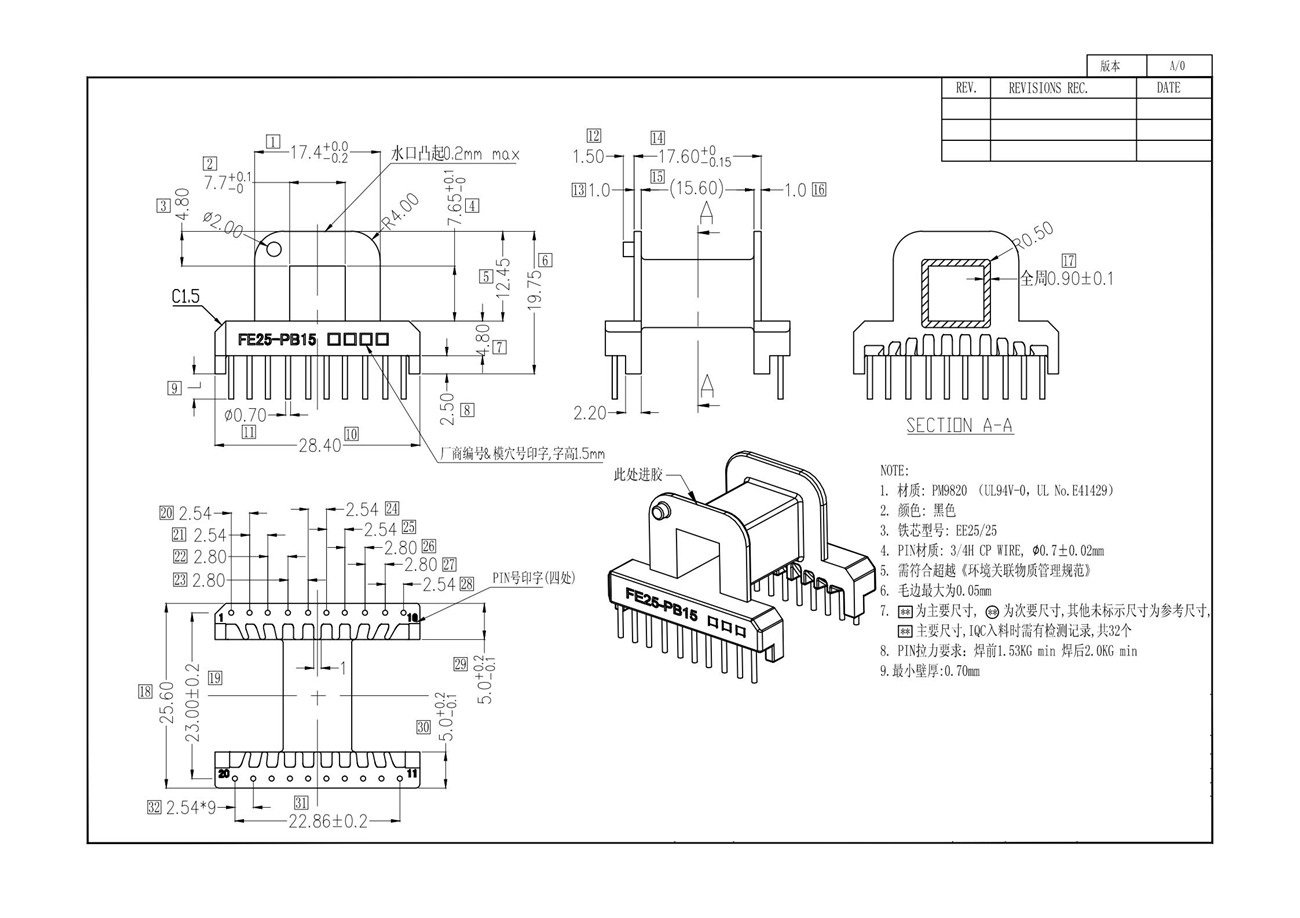

EE25 Horizontal Transformer Bobbin (10+10P) F25115

Transformer and Inductor Design for Optimum Circuit Performance. Texas Instruments 1 SLUP205. Bobbin Winding Area, AW': 1.23 cm2 Winding Area Width/Height: 2.15 / 0.62 cm

Quickreference guite to winding transformers. NO 3 correction is made for losses.

ETD29. In this section, we have listed core and bobbin geometries that are most commonly used to build switching transformers. Do reach out to us if you need a specific size that isn't listed here. You may use the data provided to finalize the transformer design and request a quote and samples. Footprint data provided is subject to change so.

Pin on Amplifier

Spread the winding evenly across entire bobbin. Wind in same rotational direction as primary winding. Finish this winding on pin(s) 11. Add 3 layers of tape, item [4], for insulation. Primary Winding (Section 2) Start on pin(s) 2 and wind 38 turns (x 1 filar) of item [6] in 2 layer(s) from left to right. At the end of 1st layer, continue to.

» Split Bobbin Transformer

right to left. On the final layer, spread the winding evenly across entire bobbin. Finish this winding on pin(s) 2. Add 1 layer of tape, item [3], for insulation. Bias Winding Start on pin(s) 6 and wind 16 turns (x 2 filar) of item [6]. Winding direction is clockwise. Spread the winding evenly across entire bobbin. Finish this winding on pin(s) 5.

Rotary Bobbins Sewing machine accessories, Sewing machine, Sewing machine repair

Approximate length of copper wire = number of turns x perimeter of bobbins. Cross-sectional area of copper. Volume = approximate length x cross-sectional area. Mass = copper density x copper volume . Primary Side calculation of Copper Weight. Perimeter of the bobbin = 1.75 x 4 = 7 inch = 0.1778 m. Therefore, the length of the turn is 0.1778

EFD22 Horizontal Transformer Bobbin(4+4P) F2228

Transformer Consulting Services Inc. • (ANSI) IEEE Std C57.12.00-2010, standard general requirements for liquid-immersed distribution, power and regulation transformers • ANSI C57.12.10-2010, safety requirements 230 kV and below 833/958 through 8,333/10,417 KVA, single-phase, and 750/862 through